The Challenge

Wax Buildup and Blockage

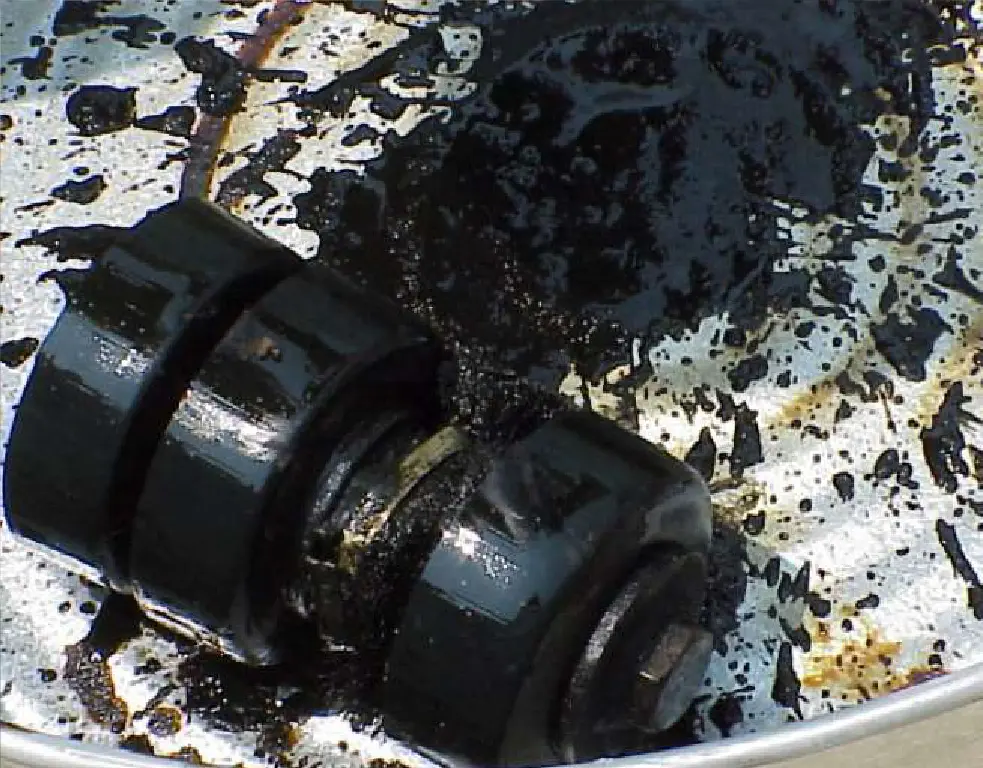

A pipeline that was not regularly cleaned experienced significant wax buildup, especially in cooler temperatures. This led to blockages that halted operations.

Problems Faced

- Pipeline Blockage: Wax accumulation restricted oil flow.

- Costly Cleaning Process: A hot oil truck was required to pressurize the line and locate the blockage.

- Operational Downtime: The pipeline was shut down throughout the cleaning and repair process.

- High Expenses: Oil had to be trucked while repairs were made, increasing operational costs.

The HCS Solution

Efficient Pipeline Cleaning

To restore the pipeline without costly downtime, HCS Pipeline Cleaner was introduced using an innovative process.

Solution Implementation

- Chemical Cleaning: Five gallons of HCS Pipeline Cleaner were applied using a wire brush tool.

- Advanced Pumping System: A gear pump with a reservoir was mounted on a company service vehicle for quick chemical insertion.

- No Shutdown Required: The pipeline remained in service while the chemical and tool effectively removed the wax buildup.

The Results

Cost Savings & Efficiency

- Minimal Residue Left: After retrieving the cleaning tool, only a small amount of wax remained.

- Pipeline Remained Operational: No shutdown was necessary, ensuring uninterrupted oil flow.

- Significant Cost Reduction: Eliminated the need for a hot oil truck and expensive trucking costs.

- Preventive Maintenance Achieved: Regular treatment with HCS Pipeline Cleaner reduced future wax buildup, lowering long-term maintenance expenses.

Project Information

Clients:

GOLDSMITH TEXAS

Category:

Business Solution

Date:

25 January, 2023

Address: